-

Characteristics of Product:

Excellent chemical stability;

Excellent thermal stability;

Excellent tensile strength;

Low thermal conductivity;

Low heat capacity;

Excellent insulation properties;

Good sound absorption

Application:

Industrial furnace wall lining;

Back lining material;

Furnace masonry expansion joints, door, roof heat insulation seal;

High temperature pipe insulation material;

Module / folded module processing material;

Fireproof coating.

Steel industry

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Furnace hot face repairs

Reheat furnaces

Ladle covers

Power generation

Boiler Insulation

Boiler Doors

Reusable Turbine Covers

Pipe Covering

Insulation of Commercial Dryers and Covers

Veneer Over Existing Refractory

Stress Relieving Furnaces

Glass Furnace Crown Insulation

Fire Protection

-

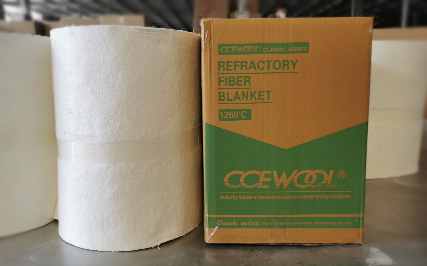

CCEWOOL® Classic series ceramic fiber blanket

Classification temperature

1260STD (2300℉)

1260 HP (2300℉)

1400AZ

(2550℉)1430HZ

(2600℉)Operation Temp(℃)

1050℃

1100℃

1200℃

1350℃

Density (kg/m3)

64/ 96/ 128/ 160(4,6,8,10lb/ft3)

Permanent Change on Heating (%), EN1094-1

After 24 hours @950℃

-

-

-

-

@1000℃

1.5

1.5

-

-

@1100℃

2.5

2.2

1.5

-

@1200℃

3

3

2

1

@1300℃

-

-

3

2

@1400℃

-

-

-

3

Tensile Strength(Kg/m3), EN1094-1 KPa

Density 64kg/m3

30

30

30

30

96kg/m3

50

50

50

50

128kg/m3

70

70

70

70

160kg/m3

100

100

100

100

Heat Conductive Co-efficient W/(m·k)(128kg/m3)

Temperature

@200℃

0.07

0.07

0.07

0.06

@400℃

0.12

0.12

0.12

0.11

@600℃

0.2

0.2

0.2

0.16

@800℃

0.3

0.3

0.3

0.23

@1000℃

0.45

0.4

0.43

0.35

Chemical Composition of ceramic blanket (%)

Al2O3

45-46

47-49

45-46

35-38

Al2O3+SiO2

≥98

≥99

-

-

ZrO2

-

-

5

15-17

Al2O3+SiO2+ZrO2

-

-

≥99

≥99

Fe2O3

≤0.8

≤0.2

≤0.2

≤0.2

Na2O+K2O

≤0.3

≤0.2

≤0.2

≤0.2

CaO+MgO

≤0.1

≤0.1

≤0.1

≤0.1

Thickness

Density kg/m3

Length

Width

mm

64

96

128

160

mm

mm

6

-

-

○

○

7200

610, 1220

13

-

√

√

○

14640

19

-

√

√

○

9760

25

○

√

√

√

7320

38

○

√

√

√

4880

50

○

√

√

-

3660

Note:

(○) and 1220mm width can be customized according to customer (order amount should not be less than the minimum order quantity)

(√) for conventional products

-

Country of customer: Turkey

Cooperation years: 10 years

Turkish customer has cooperated with us for 10 years. This customer found us at the Turkish Metallurgical Foundry Exhibition in 2010. There were more than a dozen ceramic fiber exhibitors at the exhibition. But this customer only determined to cooperate with our company and be our agent.

This customer placed an order on-site at the exhibition, expressing his determination to cooperate with us. We were moved by the customer's recognition of CCEWOOL and the positive attitude of the customer. We left all the promotional materials and samples at the exhibition site to this customer for his promotion.

The customer’s company is a 26-year-old company founded in 1994 and headquartered in Istanbul. It is one of Turkey's leading trading companies, providing a wide range of goods and raw materials to end users in Turkey's steel and foundry industries as well as customers in the Middle East and European countries. The customer's logistics distribution is very perfect. After many inspections, we decided to treat this customer as our Turkish agent, mainly selling our products to Turkey and the Middle East.

This customer first learned a lot of information about us from his European customers. Our products have been selling well in European market for 21 years. This customer values the professionalism of CCEWOOL and CCEWOOL’s influence in the European market. And Europe is also the main market for this customer.

During cooperation, this customer praised our quality and service. We have 20 years of export experience. We are familiar with international procurement standards and well aware of international customers' purchasing concerns, and solve customer’s worries about imported products. We keep track of every order from production, shipment, transportation, customs declaration, customs clearance, delivery, use, etc., and provide customers with corresponding photos and technical data, etc. We make every effort to achieve customer satisfaction.

We feel very pleased and proud for Turkish customer's recognition for CCEWOOL ceramic fiber. In the past 20 years, CCEWOOL has adhered to the branding strategy, and constantly developed new products in accordance with changes of market demand. CCEWOOL has been in refractory insulation material business for 20 years. We not only sell products but also care more about quality, service and reputation.

-

Jun

27

Country of customer: Singapore

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 10*1100*15000mm

Delivery date: Jun 27, 2024

Jun

13

Country of customer: Ukraine

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 50*610*3660mm

Delivery date: Jun 13, 2024

Jun

06

Country of customer: Ecuador

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 25*610*7200mm

Delivery date: Jun 06, 2024

May

30

Country of customer: South Africa

Cooperation years:5 years

Ordered product: Insulating Fire Brick

Product size: 76*114*228mm

Delivery date: May 30, 2024

May

23

Country of customer: Peru

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 50*610*3810mm

Delivery date: May 23, 2024

May

16

Country of customer: Ecuador

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 25*610*7200mm

Delivery date: May 16, 2024

May

10

Country of customer: Poland

Cooperation years:5 years

Ordered product: Low Biopersistent Fiber Blanket

Product size: 25*610*7320mm

Delivery date: May 10, 2024

Apr

30

Country of customer: India

Cooperation years:8 years

Ordered product: Ceramic fiber blanket

Product size: 25*610*7200mm

Delivery date: Apr 30, 2024

Apr

25

Country of customer: Italy

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 50*1020*3660mm

Delivery date: Apr 25, 2024

Apr

18

Country of customer: UK

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 25*610*7320mm

Delivery date: Apr 18, 2024

Apr

11

Country of customer: Dominican

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 25*610*7600mm

Delivery date: Apr 11, 2024

Mar

28

Country of customer: Peru

Cooperation years:5 years

Ordered product: Ceramic Fiber Bulk

Product size:

Delivery date: Mar 28, 2024

Mar

21

Country of customer: Ireland

Cooperation years:1 year

Ordered product: Ceramic fiber blanket

Product size: 25*610*7320mm

Delivery date: Mar 21, 2024

Mar

14

Country of customer: UK

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 25*610*7320mm

Delivery date: Mar 14, 2024

Mar

07

Country of customer: Singapore

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 10*1100*15000mm

Delivery date: Mar 07, 2024

Feb

29

Country of customer: Spain

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 25*940/280*7320mm

Delivery date: Feb 29, 2024

Feb

22

Country of customer: Ireland

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 25*610*7200mm

Delivery date: Feb 22, 2024

Feb

05

Country of customer: Singapore

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 10*1100*15000mm

Delivery date: Feb 05, 2024

Jan

25

Country of customer: Czech Republic

Cooperation years:10 years

Ordered product: Ceramic fiber board

Product size: 12*660/560*1160mm

Delivery date: Jan 25, 2024

Jan

18

Country of customer: Netherlands

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 25*610*7200mm

Delivery date: Jan 18, 2024

Jan

10

Country of customer: Poland

Cooperation years:8 years

Ordered product: Ceramic fiber board

Product size: 20/30*1000*1200mm

Delivery date: Jan 10, 2024

Jan

04

Country of customer: Singapore

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 10*1100*15000mm

Delivery date: Jan 04, 2024

Dec

28

Country of customer: Mexico

Cooperation years:8 years

Ordered product: Ceramic fiber paper

Product size: 3.18*610*38100mm

Delivery date: Dec 28, 2023

Dec

14

Country of customer: UK

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 25*610*7320mm

Delivery date: Dec 14, 2023

Dec

07

Country of customer: Nigeria

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 50*610*3600mm

Delivery date: Dec 07, 2023

Nov

30

Country of customer: Singapore

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 15000*1100*10mm

Delivery date: Nov 30, 2023

Nov

23

Country of customer: Australia

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 25*610*7320mm

Delivery date: Nov 23, 2023

Nov

16

Country of customer: Portugal

Cooperation years:7 years

Ordered product: Purewool ceramic fiber blanket

Product size: 7320*610*25mm

Delivery date: Nov 16, 2023

Nov

09

Country of customer: Peru

Cooperation years:4 years

Ordered product: Ceramic Fiber Bulk

Product size:

Delivery date: Nov 09, 2023

Nov

02

Country of customer: UK

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 7320*610*25mm

Delivery date: Nov 02, 2023

Oct

26

Country of customer: Singapore

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 15000*1100*10mm

Delivery date: Oct 26, 2023

Oct

17

Country of customer: Australia

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 3660*610*50mm

Delivery date: Oct 17, 2023

Oct

14

Country of customer: Italy

Cooperation years:3 years

Ordered product: Water repellent ceramic fiber blanket

Product size: 3660*610*50mm

Delivery date: Oct 14, 2023

Sep

14

Country of customer: Bulgaria

Cooperation years:7 years

Ordered product: Chopped Soluble Fiber Bulk

Product size:

Delivery date: Sep 14, 2023

Sep

07

Country of customer: Dominica

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*25mm

Delivery date: Sep 07, 2023

Jul

13

Country of customer: Peru

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Jul 13, 2023

Jul

06

Country of customer: Poland

Cooperation years:8 years

Ordered product: Ceramic fiber paper

Product size: 12000*1220*5mm

Delivery date: Jul 06, 2023

Jun

21

Country of customer: France

Cooperation years:7 years

Ordered product: Purewool ceramic fiber blanket

Product size: 3660*610*50mm

Delivery date: Jun 21, 2023

Jun

15

Country of customer: France

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 7320*610*25mm

Delivery date: Jun 15, 2023

Jun

08

Country of customer: Dominica

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 3800*610*50

Delivery date: Jun 08, 2023

May

31

Country of customer: Australia

Cooperation years:7 years

Ordered product: Soluble fiber blanket

Product size: 7320*610*25mm

Delivery date: May 31, 2023

May

18

Country of customer: Poland

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*25mm

Delivery date: May 18, 2023

May

05

Country of customer: India

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: May 05, 2023

Apr

26

Country of customer: Singapore

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 15000*1100*10mm

Delivery date: Apr 26, 2023

Apr

20

Country of customer: Guatemala

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 5080/3810*610*38/50mm

Delivery date: Apr 20, 2023

Apr

13

Country of customer: Peru

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 3810*610*50mm

Delivery date: Apr 13, 2023

Mar

23

Country of customer: Czech republic

Cooperation years:10 years

Ordered product: Ceramic fiber board

Product size: 1160*660/560*12mm

Delivery date: Mar 23, 2023

Mar

16

Country of customer: El Salvador

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*50mm

Delivery date: Mar 16, 2023

Mar

09

Country of customer: Indonesia

Cooperation years:9 years

Ordered product: Ceramic fiber blanket

Product size: 5000*300*25mm

Delivery date: Mar 09, 2023

Feb

18

Country of customer: Peru

Cooperation years:3 years

Ordered product: Ceramic Fiber Bulk

Product size:

Delivery date: Feb 18, 2023

Feb

09

Country of customer: Poland

Cooperation years:3 years

Ordered product: Soluble fiber blanket

Product size: 7320*610*25mm

Delivery date: Feb 09, 2023

Feb

02

Country of customer: Peru

Cooperation years:6 years

Ordered product: Ceramic insulation blanket

Product size: 3810*610*50mm

Delivery date: Feb 02, 2023

Jan

28

Country of customer: South Africa

Cooperation years:5 years

Ordered product: Insulating Fire Brick

Product size: 228*114*76mm

Delivery date: Jan 28, 2023

Jan

12

Country of customer: Peru

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 7320*610*25mm

Delivery date: Jan 12, 2023

Jan

05

Country of customer: Mexico

Cooperation years:7 years

Ordered product: Ceramic fiber paper

Product size: 38100*610*3.18mm

Delivery date: Jan 05, 2023

Dec

29

Country of customer: Poland

Cooperation years:7 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*20/40mm

Delivery date: Dec 29, 2022

Dec

08

Country of customer: UAE

Cooperation years:5 years

Ordered product: Water repellent ceramic fiber blanket

Product size: 3600*610*50mm

Delivery date: Dec 08, 2022

Nov

24

Country of customer: Portugal

Cooperation years:6 years

Ordered product: insulating fire brick

Product size: 1200*1000*20/40mm

Delivery date: Nov 24, 2022

Nov

17

Country of customer: Bulgaria

Cooperation years:6 years

Ordered product: Chopped Soluble Fiber Bulk

Product size: 20kg/bag

Delivery date: Nov 17, 2022

Nov

03

Country of customer: Poland

Cooperation years:7 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*10mm

Delivery date: Nov 03, 2022

Oct

27

Country of customer: Dominica

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 3600*610*50mm

Delivery date: Oct 27, 2022

Oct

20

Country of customer: Poland

Cooperation years:7 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: Oct 20, 2022

Sep

29

Country of customer: Australia

Cooperation years:6 years

Ordered product: Soluble fiber blanket

Product size: 7320*610*25mm

Delivery date: Sep 29, 2022

Sep

22

Country of customer: India

Cooperation years:7 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Sep 22, 2022

Sep

07

Country of customer: Singapore

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 15000*1100*10mm

Delivery date: Sep 07, 2022

Aug

31

Country of customer: Guatemala

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 5080/3810*610*38/50mm

Delivery date: Aug 31, 2022

Aug

17

Country of customer: UK

Cooperation years:6 years

Ordered product: Mullite Insulation Brick

Product size: 230*114*76mm

Delivery date: Aug 17, 2022

Aug

03

Country of customer: Australia

Cooperation years:6 years

Ordered product: Soluble fiber blanket

Product size: 7200*610*12/25mm

Delivery date: Aug 03, 2022

Jul

20

Country of customer: Poland

Cooperation years:7 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: Jul 20, 2022

Jul

05

Country of customer: Peru

Cooperation years:3 years

Ordered product: Ceramic Fiber Bulk

Product size: 20kg/bag

Delivery date: Jul 05, 2022

Jun

30

Country of customer: Dominica

Cooperation years:5 years

Ordered product: Ceramic insulation blanket

Product size: 7600*610*25mm

Delivery date: Jun 30, 2022

Jun

27

Country of customer: Czech

Cooperation years:10 years

Ordered product: Ceramic fiber board

Product size: 1160*660/560*12mm

Delivery date: Jun 27, 2022

Jun

22

Country of customer: Poland

Cooperation years:7 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*20/40mm

Delivery date: Jun 22, 2022

May

19

Country of customer: Bulgaria

Cooperation years:2 years

Ordered product: ceramic fiber bulk

Product size:

Delivery date: May 19, 2022

Apr

26

Country of customer: Bulgaria

Cooperation years:6 years

Ordered product: Chopped Soluble Fiber Bulk

Product size: 20kg/bag

Delivery date: Apr 26, 2022

Apr

07

Country of customer: Singapore

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 15000*1100*10mm

Delivery date: Apr 07, 2022

Mar

29

Country of customer: Australia

Cooperation years:6 years

Ordered product: Soluble fiber blanket

Product size: 7200*610*25mm

Delivery date: Mar 29, 2022

Mar

10

Country of customer: UK

Cooperation years:5 years

Ordered product: Mullite insulation brick

Product size: 230*114*76mm

Delivery date: Mar 10, 2022

Feb

10

Country of customer: Peru

Cooperation years:6 years

Ordered product: Ceramic insulation blanket

Product size: 7620*610*25mm

Delivery date: Feb 10, 2022

Jan

27

Country of customer: Dominica

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 3600*610*50mm

Delivery date: Jan 27, 2022

Jan

10

Country of customer: Ecuador

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*25mm

Delivery date: Jan 10, 2022

Dec

30

Country of customer: Bulgaria

Cooperation years:5 years

Ordered product: ceramic fiber bulk

Product size:

Delivery date: Dec 30, 2021

Dec

23

Country of customer: Poland

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 14640*45*13mm

Delivery date: Dec 23, 2021

Dec

17

Country of customer: India

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Dec 17, 2021

Dec

08

Country of customer: Saudi Arabia

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*13mm

Delivery date: Dec 08, 2021

Dec

01

Country of customer: Australia

Cooperation years:5 years

Ordered product: soluble fiber blanket

Product size: 7200*610*25mm

Delivery date: Dec 01, 2021

Nov

18

Country of customer: Australia

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Nov 18, 2021

Nov

17

Country of customer: Kenya

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 7200*1000*25mm

Delivery date: Nov 17, 2021

Nov

04

Country of customer: Poland

Cooperation years:6 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: Nov 04, 2021

Oct

27

Country of customer: Peru

Cooperation years:1 year

Ordered product: ceramic fiber bulk

Product size:

Delivery date: Oct 27, 2021

Oct

20

Country of customer: United Kingdom

Cooperation years:5 years

Ordered product: Mullite insulation brick

Product size: 230*114*76mm

Delivery date: Oct 20, 2021

Oct

14

Country of customer: Poland

Cooperation years:6 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*30/40mm

Delivery date: Oct 14, 2021

Oct

13

Country of customer: Dominica

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 7600*610*25mm

Delivery date: Oct 13, 2021

Oct

13

Country of customer: Portugal

Cooperation years:6 years

Ordered product: ceramic insulation blanket

Product size: 7200*610*25mm

Delivery date: Oct 13, 2021

Sep

17

Country of customer: Ecuador

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*25mm

Delivery date: Sep 17, 2021

Sep

17

Country of customer: Spain

Cooperation years:1 year

Ordered product: large size ceramic fiber board

Product size: 2000*1000*50mm

Delivery date: Sep 17, 2021

Aug

04

Country of customer: Australia

Cooperation years:5 years

Ordered product: soluble fiber blanket

Product size: 3660*610*50mm

Delivery date: Aug 04, 2021

Jul

28

Country of customer: Poland

Cooperation years:6 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*30/40mm

Delivery date: Jul 28, 2021

Jul

21

Country of customer: Bulgaria

Cooperation years:5 years

Ordered product: soluble fiber bulk

Product size: custom made

Delivery date: Jul 21, 2021

Jul

14

Country of customer: Guatemala

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 5080/3810*610*38/50mm

Delivery date: Jul 14, 2021

Jul

07

Country of customer: United Kingdom

Cooperation years:5 years

Ordered product: Mullite insulation fire brick

Product size: 230*114*76mm

Delivery date: Jul 07, 2021

Jun

01

Country of customer: Poland

Cooperation years:6 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: Jun 01, 2021

May

28

Country of customer: Indonesia

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: May 28, 2021

Apr

29

Country of customer: Korea

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*20/25mm

Delivery date: Apr 29, 2021

May

25

Country of customer: Guatemala

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 5080*610*20/25mm

Delivery date: May 25, 2021

Apr

24

Country of customer: Peru

Cooperation years:1 year

Ordered product: ceramic fiber bulk

Product size:

Delivery date: Apr 24, 2021

Apr

12

Country of customer: Philippines

Cooperation years:1 year

Ordered product: Ceramic fiber blanket

Product size: 3600*610*50mm

Delivery date: Apr 12, 2021

Mar

18

Country of customer: Poland

Cooperation years:6 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*20/25mm

Delivery date: Mar 18, 2021

Mar

12

Country of customer: Singapore

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 15000*1100*10mm

Delivery date: Mar 12, 2021

Feb

04

Country of customer: Indonesia

Cooperation years:8 years

Ordered product: Ceramic fiber blanket

Product size:

Delivery date: Feb 04, 2021

Jan

28

Country of customer: Salvador

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*25/50mm

Delivery date: Jan 28, 2021

Dec

15

Country of customer: Russia

Cooperation years:1 year

Ordered product: Ceramic fiber board

Product size: 1200*600*20/40mm

Delivery date: Dec 15, 2020

Dec

08

Country of customer: Czech Republic

Cooperation years:8 years

Ordered product: Ceramic fiber board

Product size: 1160*660/560*12mm

Delivery date: Dec 08, 2020

Nov

30

Country of customer: Indonesia

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 3660*610*50mm

Delivery date: Nov 30, 2020

Nov

20

Country of customer: Poland

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Nov 20, 2020

Nov

16

Country of customer: Poland

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 7660*610*50mm

Delivery date: Nov 16, 2020

Nov

06

Country of customer: Dominica

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 7600*610*25mm

Delivery date: Nov 06, 2020

Nov

02

Country of customer: Poland

Cooperation years:4 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*50mm

Delivery date: Nov 02, 2020

Sep

25

Country of customer: United Kingdom

Cooperation years:4 years

Ordered product: soluble fiber blanket

Product size: 7320*610*25mm

Delivery date: Sep 25, 2020

Sep

18

Country of customer: Ecuador

Cooperation years:1 years

Ordered product: Ceramic fibre blanket

Product size: 7620*610*25mm

Delivery date: Sep 18, 2020

Sep

11

Country of customer: Poland

Cooperation years:2 years

Ordered product: Ceramic fibre blanket

Product size: 7320*610*25mm

Delivery date: Sep 11, 2020

Sep

05

Country of customer: Portugal

Cooperation years:5 years

Ordered product: Ceramic fibre blanket

Product size: 7200*610*25mm

Delivery date: Sep 05, 2020

Aug

28

Country of customer: Poland

Cooperation years:5 years

Ordered product: Ceramic fibre blanket

Product size: 7320*610*25mm

Delivery date: Aug 28, 2020

Aug

21

Country of customer: Malaysia

Cooperation years:6 years

Ordered product: Ceramic fiber module

Product size: 300*300*100mm

Delivery date: Aug 21, 2020

Aug

14

Country of customer: Poland

Cooperation years:5 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: Aug 14, 2020

Aug

03

Country of customer: Poland

Cooperation years:2 years

Ordered product: Ceramic fibre blanket

Product size: 7320*610*25mm

Delivery date: Aug 03, 2020

Jul

15

Country of customer: Russia

Cooperation years:1 year

Ordered product: Ceramic fiber board

Product size: 1200*600*20/40mm

Delivery date: Jul 15, 2020

Jul

08

Country of customer: UK

Cooperation years:4 years

Ordered product: soluble insulation fiber blanket

Product size: 7320*610*25mm

Delivery date: Jul 08, 2020

Jul

02

Country of customer: United Kingdom

Cooperation years:4 years

Ordered product: mullite insulation fire brick

Product size: 230*114*76mm

Delivery date: Jul 02, 2020

Jun

24

Country of customer: Poland

Cooperation years:5 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: Jun 24, 2020

Jun

17

Country of customer: Australia

Cooperation years:4 years

Ordered product: Soluble insulation fiber blanket

Product size: 7200*610*25/12mm

Delivery date: Jun 17, 2020

Jun

10

Country of customer: Egypt

Cooperation years:10 years

Ordered product: Insulation soluble fiber blanket

Product size: 7200*610*25mm

Delivery date: Jun 10, 2020

Jun

03

Country of customer: Guatemala

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 5080*610*38mm/25mm/50mm

Delivery date: Jun 03, 2020

May

27

Country of customer: Indonesia

Cooperation years:6 years

Ordered product: Ceramic fibre blanket

Product size: 5000*150*25mm

Delivery date: May 27, 2020

May

07

Country of customer: Turkey

Cooperation years:6 years

Ordered product: Ceramic fiber board

Product size: 1200*1000*25mm

Delivery date: May 07, 2020

Apr

28

Country of customer: Spain

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 7320*940/280*25mm

Delivery date: Apr 28, 2020

Apr

22

Country of customer: Australia

Cooperation years:4 years

Ordered product: Soluble fiber blanket

Product size: 7200*610*25mm

Delivery date: Apr 22, 2020

Apr

15

Country of customer: Portugal

Cooperation years:4 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Apr 15, 2020

Apr

08

Country of customer: Poland

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 7320*610*25mm

Delivery date: Apr 08, 2020

Apr

01

Country of customer: UK

Cooperation years:4 years

Ordered product: Soluble fiber blanket

Product size: 7320*610*25mm

Delivery date: Apr 01, 2020

Mar

03

Country of customer: Indonesia

Cooperation years:8 years

Ordered product: Ceramic fiber blanket

Product size: 3600*610*50mm

Delivery date: Mar 03, 2020

Feb

28

Country of customer: USA

Cooperation years:2 years

Ordered product: Ceramic fiber blanket

Product size: 4876*1220*51mm

Delivery date: Feb 28, 2020

Mar

18

Country of customer: India

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Mar 18, 2020

Jan

16

Country of customer: Indonesia

Cooperation years:8 years

Ordered product: Insulation rock wool board

Product size: 1200*600*50mm

Delivery date: Jan 16, 2020

Jan

13

Country of customer: Bosnia and Herzegovina

Cooperation years:3 years

Ordered product: Ceramic fiber blanket/ bulk

Product size: 5000*1000/1220*30mm

Delivery date: Jan 13, 2020

Jan

04

Country of customer: Canada

Cooperation years:5 years

Ordered product: Soluble ceramic fiber blanket

Product size: 7320*610*25mm

Delivery date: Jan 04, 2020

Oct

12

Country of customer: Bulgaria

Cooperation years:6 years

Ordered product: Bio soluble fiber blanket

Product size: 7320*610*25mm

Delivery date: Oct 12, 2019

Apr

22

Country of customer: Australia

Cooperation years:8 years

Ordered product: Soluble fiber insulation blanket

Product size: 7320*610*25mm

Delivery date: Apr 22, 2019

Mar

14

Country of customer: Spain

Cooperation years:3 years

Ordered product: Ceramic fiber blanket

Product size: 7320*940/280*25mm

Delivery date: Mar 14, 2019

Jan

10

Country of customer: BiH

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 5000*1000*30mm

Delivery date: Jan 10, 2019

Dec

20

Country of customer: Portugal

Cooperation years:10 years

Ordered product: Ceramic fiber blanket

Product size: 3660*610*50mm

Delivery date: Dec 20, 2018

May

23

Country of customer: Peru

Cooperation years:4 years

Ordered product: rock wool products

Product size: 1000*600*50/25mm

Delivery date: May 23, 2018

May

14

Country of customer: United Arab Emirates

Cooperation years:12 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: May 14, 2018

Dec

19

Country of customer: Portugal

Cooperation years:6 years

Ordered product: Ceramic fiber blanket

Product size: 7200*610*25mm

Delivery date: Dec 19, 2017

May

04

Country of customer: Egypt

Cooperation years:7 years

Ordered product: Ceramic fiber blanket/board/paper

Product size: 7200*610*25mm

Delivery date: May 04, 2017

Mar

23

Country of customer: Argentina

Cooperation years:5 years

Ordered product: Ceramic fiber blanket

Product size: 7620*610*25mm

Delivery date: Mar 23, 2017

Mar

08

Country of customer: Tunisia

Cooperation years:6 years

Ordered product: Insulating fire brick

Product size: 230*114*65/75mm

Delivery date: Mar 08, 2017

Jan

25

Country of customer: Turkey

Cooperation years:8 years

Ordered product: Soluble fiber blanket

Product size: 3600*610*50mm

Delivery date: Jan 25, 2017

-

Zambia

Mar 24, 2020

Hello Mr James . confirmation of customer satisfaction is 100% .will be getting back to you soon for once we get the big order for 350metres.

Regards.

Spain

Mar 05, 2020

Dear Rosen:

I would like you to inform that customer received shipment, and I am glad to say that they are satisfied with product quality.

Their idea is to buy from you about 10 containers like this per year, about a 1x40HQ per month or 1.5 month, next order will be placed shortly, customer is asking us if with this program you can make price a little bit better.

Best regards.

Peru

Feb 12, 2020

Either way, I saw your company video, CCEWOOL looks so nice and seems so easy to work with!

Australian

Jan 21, 2020

We have only heard positive feedback about your products from our current customers using them. Thank you for all the work you are doing for us.

Regards.

Sri Lanka

Jan 15, 2020

Dear Mr. James,

Thanks for follow up.

It is great to see that you are following up after selling the products. We are very much interested about your service.

We are in a process of using the products and we will send the answers for questionnaire at our earliest.

For now we are very much satisfied about the product/ packaging and physical appearance.

Thank you

Saldo

Dec 16, 2019

Dear James,

Thank you, is good quality we received good feedback from our clients.

We'll check inventories in January and let you know if we need more.

Best Regards

UK Customer

Nov 20, 2019

Dear Rosen

On a positive note,the blanket and board seems ok and the packaging of all products looks more professional than Chinese competitors.

Pakistan

Oct 23, 2019

Dear Sir,

We have received positive feedback from end user on your supplied ceramic wool. Thanks for all your support, as we are now marketing your products here, so we will be requiring authorization letter from you (sample attached).

We request you to please keep us in loop if any of our client will contact you directly.

Thanks for your trust and support.

Regards

Iran

Oct 08, 2019

Hi dear Rosen

Good morning

I know CCEWOOL.

I see your products in market.

And also visited your website.

UK Customer

Sep 19, 2019

Dear Rosen

We have been promoting your products to our customers as better quality than the usual Chinese manufacturers.

Turkey

Aug 08, 2019

Dear Rosen,

It has been a long time since we have got our first contact in Ceramitec 2012 in Munich and it is a shame we could not have initiated a business.

I know CCEWOOL is an established brand and have good quality products, there is no question about that.

As you know very well, the prices in Turkey are low, this is because the volume is high and there are several users that put price before the quality.

As our customer is composed of customers who value performance / price ratio. Therefore I would very much like to work with CCEWOOL.

There are several companies from China that are offering insulation products at much lower prices but we are not interested in them.

Dominica

Aug 05, 2019

Hello

Your product is good quality

We will buy more coming soon

Best Regards

UAE Customer

Jul 24, 2019

UAE customer: I like CCEWOOL. I can do this project.

Roson: We will fully support you.

UAE customer: I am waiting for your offer. Please send me early in the morning.

Turkey

Jun 10, 2019

Dear James

Thank you very much for your kindness,

Our samples has received our Company. Your packing and label is really great.

Many thanks.

Argentina

May 21, 2019

Dear Sophia

We have received the products and were very good! We are very happy, we will do good business. Provided that in Argentina we sell only to us. Since we'll take your brand to the highest in the market.

Thank you very much.

Best regards.

Peru

Feb 13, 2019

Cici, how are you?

We are surprised with the quality of its products and good prices.

At the latest, within a month, if all goes well we will be doing a new order of rockwool and / or ceramic fiber blankets.

I will appreciate your patience.

Best regards.

Russia

Jan 30, 2019

Dear Mr.Rosen

Today received from your samples!!!

Very quickly.Thank you.You are a true professional.

Please send prices for study.

Iran

Nov 29, 2018

Dear Rosen

Thanks now we make block and installation in shuttle kiln. I think material blanket is very good. Mortar we use and it was very good. I am waiting for beginning new kiln and check the quality of blanket.

Holland

Oct 15, 2018

Hello Alice,

The process looks perfect.

Please send me our order no. so that i can put the pictures in the right filling.

Best regards

Portugal

Sep 28, 2018

Dear Mr. ROSEN PENG

Dear Mr. JAMES ZHU

Our order for insulating materials delivered in May, 2018 were successfully mounted on the furnace and the results after 3 months of operation are positive. Thank you for this first delivery and in consequence we are glad to continue our cooperation for other applications in our field of activity. We hope CCEWOOL continues to be our reliable partner.

You have attached some pictures on this application.

Best regards.

Ecuador

Aug 02, 2018

Hi Lansing

Everything arrived OK. The rock wool quality is perfect. I think we'll make a second order in March.

Thanks for your help.

B. regards

S.Africa

Jul 18, 2018

Hi, Rosen

Thanks your for you fibre, it is really good product and we are very happy with your product.

Korea

May 22, 2018

I wish we would be good partner in future. Thanks Qing, Tks a lot. Fighting!

Iran

Feb 05, 2018

Thank you so much for your kind hospitality. I hope we have a good cooperation in future.

Indonesia

Jan 24, 2018

Rosen:

Thanks for your company hospitably. It has been a pleasure to cooperate wit you.

Good luck with you and teams.

Pakistan

Dec 13, 2017

Lansing: will get back with new order soon

Rosen: very much satisfied with products and very lovely people.

Egypt

Sep 13, 2017

Dear Mr. Rosen

How are you!

All our clients told us the quality of your brand is very good we will distribute your brand in very place in Egypt. We will sent you new order very soon.

Hope to cooperate with you.

Bulgaria

Jul 17, 2017

Dear Mr. Rosen Peng

Thank you very much for your email. Thank you also for your honest comments

We agree with all your comments and probably for now we will continue to buy insulating bricks from Europe.

If we decide to buy from China you will be the first person we contact.

Thank you very much once again for your kind attention to us.

With best regards and wishes for a succeessul business.

Bulgaria

Nov 16, 2016

Dear Monica

In Tuesday received the container. Thank you for it!

Mr. Valen is very happy of the quality of the goods and he is sending hes special greatings to your and Mr. Rosen! We will keep in touch with you.

I wish you great week and weekend.

BR

Anna