Jun. 03, 2016

Basalt rock wool and slag wool are collectively referred to mineral wool, there are a lot of things in common about production process, fiber morphology, thermal conductivity and non-inflammability. So it’s easily to view the two as the same thing, even some people think that the slag wool is whiter, is purer than grey-green rock wool, this is a misunderstanding. Although they all belong to mineral wool, there are still some differences can’t be ignored. The main cause of these differences is the different raw material.

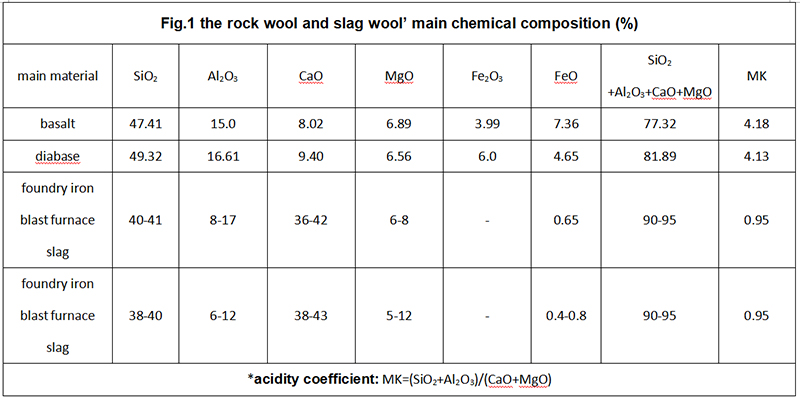

Comparison of the chemical composition and acidity coefficient of rock wool and slag wool.

The main raw material of slag wool is blast furnace slag or other metallurgical slag, CCEWOOL rock wool adopt basalt or diabase as main raw material.

Fig1. Shows that Blast furnace slag’ chemical feature is that SiO2+Al2O3+CaO+ MgO content is high to 90%-95%, but Fe2O3+ FeO content is less than 1%, CCEWOOL basalt rock wool board’ chemical feature is SiO2+Al2O3+CaO+ MgO content is high to 77%-83%, 10% lower than blast furnace slag, but SiO2+Al2O3+CaO+ MgO content is about 11%, the maximum is 17%. Thereby calculating CCEWOOL basalt rock wool board’ MK acidity coefficient is 1.5 or more even up to 2.0 or more, and the slag wool’ acidity coefficient MK is about 1.2.