Oct. 14, 2016

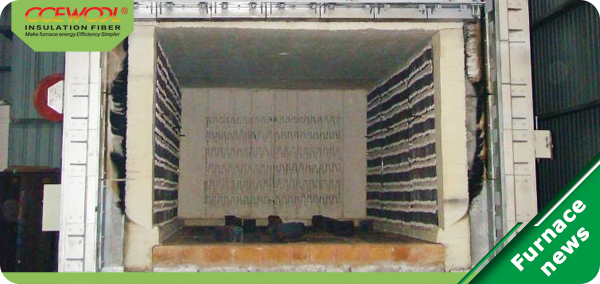

CCEWOOL refractory lining ceramic fiber module has its own advantages as lining material in the industrial furnace.

Using anchoring nails to fix stainless steel liner and insulation bulk on the furnace shell is the traditional layer blanket type kiln lining structure, so, which will make the heat in the industrial kiln transmit to the furnace shell through anchoring nails. Because there are up to tens of thousands of anchor nail in the annealing furnace, so this makes the furnace heat dissipation is relatively high.

The CCEWOOL refractory lining ceramic fiber module as an industrial furnace lining is also using anchoring nails to fix the ceramic fiber module on the furnace shell. The anchoring nails are not directly contacted with heat in the furnace, so that will not cause unnecessary heat loss. In order to be able to protect CCEWOOL refractory lining ceramic fiber module effectively, sewn the insulation aluminum cloth on the module, which has the advantages of deformation resistant and repairmen convenient compared with the traditional stainless steel liner.

Through the actual survey found that when the industrial furnace’s temperature reached 800 degrees Celsius, by using the relevant instruments for measurement we can find that welding of anchoring nails’ temperature presents the peak shape distribution in the traditional layer blanket type kiln lining structure. The temperature of furnace shell reached between 60-80℃.

It can be seen, the temperature distribution of CCEWOOL refractory lining ceramic fiber modular kiln lining wall, because there is no anchor nail to diffuse the heat that can be greatly reduced the degree of heat conduction. In this way, the temperature of the furnace shell can be reduced from the whole and the temperature distribution is more uniform. It is found that the temperature of the furnace shell of the industrial kiln is between 40 and 50C.

It is obviously when compare traditional layer blanket type kiln lining structure and the CCEWOOL refractory lining ceramic fiber module. CCEWOOL refractory lining ceramic fiber module has significant results in heat insulation and sealing effect in industrial furnace lining, greatly reducing the heat loss.

CCEWOOL refractory lining ceramic fiber module is made from the corresponding ceramic fiber material acupuncture blanket processed in dedicated machines according to customer drawings. When furnace inner wall lined by Ceramic fiber module, the module expand into different directions, so that the extrusion between the modules to make the entire module forming a seamless whole. Various shapes of SS304 / SS310 anchors are available.

The information above mentioned the advantages of CCEWOOL refractory lining ceramic fiber module in the industrial furnace lining, hoping it will give some help to kiln and furnace constructers.