Aug. 08, 2016

Recently ceramic fiber’s application respect in high temperature sintering furnace is growing. The ceramic fiber is used in all kinds furnaces based on the good thermal insulation, easy installation, small heat storage features, has very high energy-saving efficient.

The most important performance of ceramic fiber is diameter and thermal stability. Commonly used in ceramic industry is Al2O3, SiO2 fiber, according to the level of Al2O3 content into different application range, also can add the Cr2O3 material to improve the refractory and oxidation resistance performance. Generally the more Al2O3 content, lower Fe2O3 content, the fiber product more whiter. The thermal stability is more important. The thermal liner shrinkage of 1260 grade ceramic fiber is about 3%. The thermal shrinkage will effect the thermal stability directly. Due to the low thermal conductivity, light weight and low density, adopt the light weight steel frame when construct the furnace, thus the ceramic furnace’s development steps into the “lightweight furnace” time. Ceramic fiber’s low heat storage suits for the rapid heating and cooling. Ceramic fiber is flexible, can be special shaped into different shapes product with good mechanical vibration and shock resistance ability and thermal stability. These advantageous will promote the new type furnace even the ceramic industry development.

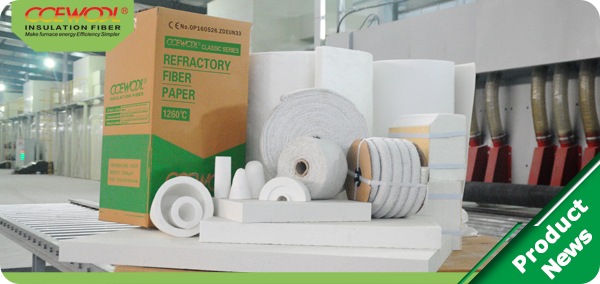

Now CCEWOOL ceramic fiber products including the ceramic fiber blanket/board/module/paper/textile and special shaped ceramic fiber. The service temperature is 950--1350C, under special circumstances, can be work above the max temperature for a short time.