Sep. 07, 2020

2. The role of mullite fiber in lightweight mullite insulation brick

Mullite fiber’s AL2O3 content is 72.34%. Its main crystal phase is mullite. It is a polycrystalline fibrous heat-insulating refractory material. Mullite fiber integrates crystal material and fiber material, has high thermal shock stability and elasticity, can withstand high temperature of 1500℃, and is a new type of ultra-light thermal insulation material. It has the high temperature resistance and erosion resistance of mullite phase, and also has the characteristics of fiber, such as softness, elasticity, and certain tensile strength. Therefore, the mullite fiber can improve the strength and high temperature stability of the lightweight mullite insulation brick

3. The influence of waste polystyrene foam ball content on the performance of lightweight mullite insulation brick.

Waste polystyrene foam is used as a pore-forming material, which can be burned when the temperature reaches a certain value, leaving a large number of pores. The size of the pores is mainly determined by the size of the polystyrene foam balls. Since the air with very low thermal conductivity plays a good thermal insulation effect in the pores, the existence of a certain amount of pores will reduce the thermal conductivity of the thermal insulation brick and improve the thermal insulation performance of the lightweight mullite insulation brick. However, too many pores will affect the strength of the brick. At the same time, due to too many pores, a large number of pores will be connected and form large open pores, which will reduce the thermal insulation performance of lightweight mullite insulation brick.

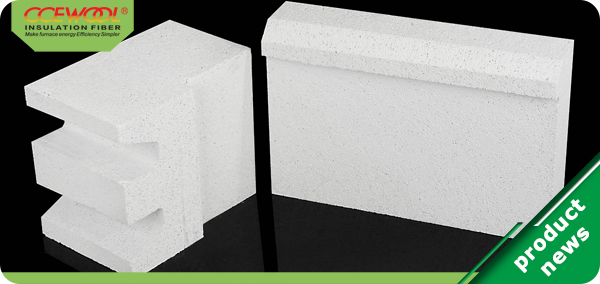

Lightweight mullite insulation brick is produced with waste polystyrene foam with a certain size as the pore-forming material, mullite fiber as the reinforcing material, and the combined clay and swelling rock as the thermal insulation material. Using lightweight mullite insulation brick in industrial furnaces can greatly reduce heat loss, save energy, and reduce the weight of thermal equipment. The process is simple and the cost is low.