Jan. 23, 2017

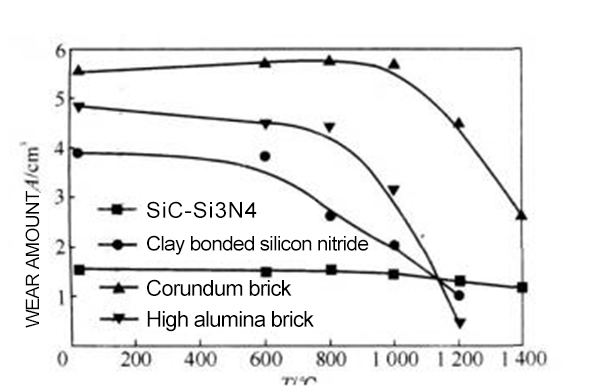

Figure 1 is the relationship curve of four CCEWOOL firebrick wearing capacity and test temperature.

It can be seen from Figure 1: there is a common characteristic on high temperature wearing curve of refractory material high-alumina brick, corundum brick and clay-bonded silicon carbide brick oxide (or oxide combined): in a certain temperature range, the wearing changing amount is not really big; but when the temperature exceeds a certain value, a significant reduction in wearing condition. The reason is that when the temperature rises, there is a change from elastic to plastic in CCEWOOL firebrick internal structure. When the material is in the elastic temperature range, with the temperature increasing, the material structure has no change, so the change in the wear quantity is not big. When the material is at the plastic temperature stage, such as high-alumina brick plastic stage is 800C-1200C, a small amount of low-melting point mineral is melting (or glass phase softening) and deformation, so the material plasticity, under the high temperature conditions, the plasticity has a certain buffer effect on the impact of the wear medium. The plastic deformation of the material will absorb the impact kinetic energy of wear medium, hinder the crack generation and expansion, so wearing has been significantly reduced. For high-alumina bricks, with the increase of temperature, the plasticity of the material increases, and the wear loss decreases.

Although the internal structure of CCEWOOL refractory bricks changes from elasticity to plasticity, the material and the bonding phase varies, the material appears different plastic temperature, the corresponding abrasion of the material begins to be greatly reduced and the temperature points are also different. It can be seen from Figure 1, corundum brick wear began to reduce at the temperature of 1000C, while the high-alumina brick at 800C. Because of the high content of impurities in high-alumina bricks, will produce liquid at lower temperatures, so that the material is in a plastic state, the amount of wear began to significantly reduce. The same reason, clay-bonded silicon carbide brick wear began to reduce drastically at the temperature point of about 600C. The high temperature wear curve of the non-oxide material silicon nitride bonded silicon carbide brick has another characteristic that the amount of wear does not vary substantially over the test temperature range and the wear-temperature curve approaches the horizontal.

In addition to providing a full range of ceramic fiber products, CCEWOOL can also provide clay bricks, CCEWOOL refractory bricks, mullite lightweight insulation bricks, and provide furnace energy saving solutions according to different application areas and industry sectors. I hope to be helpful.