May. 14, 2018

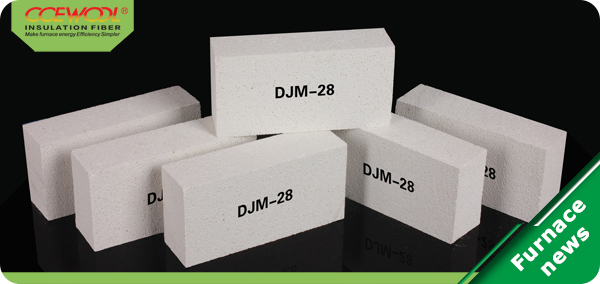

When building furnace with lightweight insulation fire brick, the brick seam is strictly controlled within 2mm; The burner block (contact fire part) is built with light mullite brick, and the fiber blanket should be pressed hard. Expansion joint of high aluminum brick should use high aluminum silicate fiber blanket, expansion joint of other parts should use ordinary aluminum silicate fiber blanket.

The thin brick energy saving roller kiln needs to be light, light and energy-saving, and it has higher requirements for thin brick roller kiln refractory material. The development trend of refractory materials for thin brick roller kiln is as follows:

1. The lightweight insulation fire brick is developing to reduce the volume density, increase the thermal shock resistance, increase the mechanical strength, reduce the linear change on reheating, improve the insulation performance, extend the service life and more economical. The improvement for the bricks for working surface of furnace with temperature higher than 1500℃ is especially hard.

2. Refractory fiber products will be more widely used in the future. And all refractory fiber furnace will be more. Durability and resistance of chemical attack of refractory fiber products should be further improved. And the improvement of refractory fiber products used in high temperature furnace(Higher than 1300℃) is difficult too.

3. Refractory material used in other parts like roller of firing zone of roller kiln and high speed burner and nozzle all need further improvement.

There are many contradictions in the development of refractory materials, such as the contradiction between light quality and service life and strength, and the contradiction between light and high temperature mechanical strength. As these contradictions continue to be solved, the thin brick roller kiln will develop to a higher level.

Above is the application of lightweight insulation brick in roller kiln. Hope this can bring help to furnace builders and contractors.