May. 30, 2018

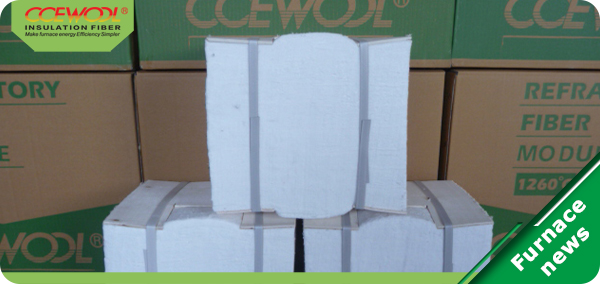

Fire-resistant ceramic fiber module product description:

The refractory ceramic fiber module is a new refractory lining product replaces the traditional refractories to simplify and accelerate the construction of kiln furnaces and improve the integrity of the lining, promote the progress of the furnace masonry technology.

Fire-resistant ceramic fiber module features:

Excellent chemical stability; Excellent thermal stability; Excellent elasticity. Module is in pre-compression state, after the furnace lining is completed, the expansion of the module makes the lining seamless, and can compensate the shrinkage of the fiber lining, in order to improve the thermal insulation of the fiber lining Performance, good overall performance; excellent thermal stability and thermal shock resistance; ceramic fiber modules installed quickly, and anchors installed on the wall lining cold surface, can reduce the anchor material requirements. According to the customer's different furnaces for insulation design and construction training.

Refractory ceramic fiber module anchor:

The use of special anchors for fiber block is on the cold side of the refractory ceramic fiber module, and its structure depends on the material of the insulating material, the atmosphere of the furnace, the structure of the fiber composite block and the location of the insulation. The structural form includes module-specific angle iron anchors, butterfly anchors, diamond anchors, empty hanging anchors, corner anchors, folding block holders, U-shaped nails, fast cards, rotating cards, Wear ribs, screw nuts, V-nails, etc.

Typical applications of refractory ceramic fiber modules:

Petroleum industry furnace lining insulation; metallurgy industry furnace lining insulation; ceramics, glass and other building materials industry furnace lining insulation; heat treatment industry heat treatment furnace lining insulation; other industrial furnace lining.